Description

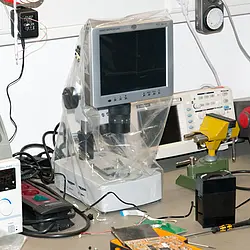

Workshop Micromonocular PCE-VM 21

Multipurpose micromonocular ideal for electronics repair, quality assurance testing, medical instrument reprocessing inspections and more

The PCE-VM 21 consists of an optical micromonocular, CCD camera and LCD screen. Due to the 75-fold magnification, it is possible to view very small parts, electronics and even medical instruments very clearly. The PCE-VM 21 inspection micromonocular reduces eye strain during soldering of printed circuit boards (PCBs), investigating of material defects on metal surfaces, and inspecting surgical implements for reprocessing, making the PCE-VM 21 industrial, healthcare or food / hygiene micromonocular a vital addition to your plant, shop, production line, quality assurance laboratory or instrument reprocessing clean room.

More information

Digital micromonoculars provided with the USB interface and possibilities of connection to the camera and PC have become widely popular in many spheres.  Workshops’ equipment may be versatile, but particularly digital micromonocular is an indispensable must-be device that may be applied for numerous tasks. Modern micromonocular is of a relatively small size and very convenient to operate. Due to the accessories it may be very reliably secured on the table and the tasks can be not only carried out, but the whole process may be demonstrated on the monitor, or on the computer screen to a larger number of people. Not only industrial, medical, biochemical or educational laboratories, but also various workshops use the USB digital micromonocular not only for research and service, but also for demonstrating and educational purposes. The workshop may be small and specialize on different insignificant repairs, or really big one, like a professional service centre, it may be a jewellery or watch workshop – anywhere where the precise and accurate examination and eventually repair is needed, the micromonocular on a flexible arm and connected with the display turns out to be a very helpful device.

Workshops’ equipment may be versatile, but particularly digital micromonocular is an indispensable must-be device that may be applied for numerous tasks. Modern micromonocular is of a relatively small size and very convenient to operate. Due to the accessories it may be very reliably secured on the table and the tasks can be not only carried out, but the whole process may be demonstrated on the monitor, or on the computer screen to a larger number of people. Not only industrial, medical, biochemical or educational laboratories, but also various workshops use the USB digital micromonocular not only for research and service, but also for demonstrating and educational purposes. The workshop may be small and specialize on different insignificant repairs, or really big one, like a professional service centre, it may be a jewellery or watch workshop – anywhere where the precise and accurate examination and eventually repair is needed, the micromonocular on a flexible arm and connected with the display turns out to be a very helpful device.  The whole process may be documented (good-quality pictures) for a later procession and analysis. Due to the adjustable illumination of an object to be examined, magnification, through the workshop micromonocular the smallest invisible to an eye defects and damages can be detected or such processes as, for example, soldering may be carried out. The distance to the micromonocular, angle, size of the examined part – all parameters can be measured and registered. If necessary, the data from the workshop micromonocular can all be transferred to the PC and even printed (for example, for the customer).

The whole process may be documented (good-quality pictures) for a later procession and analysis. Due to the adjustable illumination of an object to be examined, magnification, through the workshop micromonocular the smallest invisible to an eye defects and damages can be detected or such processes as, for example, soldering may be carried out. The distance to the micromonocular, angle, size of the examined part – all parameters can be measured and registered. If necessary, the data from the workshop micromonocular can all be transferred to the PC and even printed (for example, for the customer).

– Continuous

magnification from 10 … 75 times

– Adjustable height for viewing of larger objects

– Transmitted light and incident light illumination

– Data transfer to PC via USB 2.0 connection

– User-friendly menu in 8 different languages

– Screen resolution of 800 x 600 pixels

– Fixed-increment, crossed-scale reticle for orientation purposes

– Direct viewing on the LCD display

– Digital video recording functionality

– Aluminum carrying case

Specification

| Total unit | |

| Display | 8” LCD |

| Resolution | 800 x 600 pixels |

| Magnification | 10 … 75 times, continuous The magnification is the ratio between the object as observed on the screen and the actual size of the object. Relevant parameters are the enlargement of the lens / CCD eyepiece and size of the CCD lens / display. |

| Field of view | 13.5 mm x 10 mm / 2.1 mm x 1.5 mm 0.5 in x 0.4 in / 0.08 in x 0.06 in |

| Power supply | 100 … 240V AC, 50/60 Hz |

| Optical object lens of the micromonocular | |

| Focus of the CCD eyepiece | 0.5 times |

| Focus the main optical lens | 0.7 times … 4.5 times |

| Focus of the total optical lens | 0.35 times … 2.25 times |

| Working distance | 95 mm / 3.7 in |

| CCD camera | |

| Display chip | Sony |

| Horizontal resolution | 700 TVL |

| Light source | Reflected and transmitted light, lighting adjustable |

| Video output | 1.0Vp-p, 75 Ω |

| Video mode | PAL |

| Operating voltage | 12V DC |

| Connections | USB 2.0, AV out |

| System requirements | Windows 2000 |

| Working height | Min. 40 mm, max. 210 mm / Min. 1.6 in, max. 8.3 in |

| Power supply | 100 … 240V AC, 50/60 Hz |

| Dimensions | Baseplate: 235 mm x 155 mm x 64 mm / .3 in x 6.1 in x 2.5 in |

| Height of the vertical axis | 250 mm / 9.8 in |

| Weight | Approx. 4.8 kg / 10.6 lbs |

| Halogen lamp | |

| Operating voltage | 100 … 240V AC, 50/60 Hz |

| Upper lamp | 10W / 12V |

| Lower lamp | 10W / 12V |

Delivery monocular

1 x PCE-VM 21 micromonocular

1 x USB interface cable

1 x Video cable

1 x Power cable

1 x Dust cover

1 x Aluminum carrying case with key

1 x Object plate, glass

1 x Contrast plate, black / white

1 x Spare bulb for incident light illumination

1 x Spare bulb for transmitted light illumination

1 x Spare fuse

1 x Cleaning cloth

1 x User manual